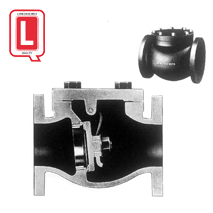

Swing Check Valve, Flanged End

Fig 1790 IBBM

Fig 1790-DP

Fig 1792 Iron

Design provides full flow with minimum pressure loss and permits free action of the disc. Valves may be used in either horizontal or vertical lines. Two body-trim combinations: All-Iron or IBBM. Bronze mounted (IBBM) models are recommended for use with oil, steam, water, air, gas and other fluids that do not attack bronze. All-Iron valves are for use with fluids which attack bronze but not iron.

Bodies and Caps

Close grained cast iron. Flanged ends.

Trim for IBBM Valves:

Discs and Seat rings are Bronze Faced for proper sealing. Solid bronze discs for 2″ – 4″; iron with bronze facings on 5″ and larger sizes.

Disc carrier pins: Silicon bronze. Renewable.

Seat rings: Bronze faced. Regrindable seating surfaces.

Trim for All-Iron Valves:

Discs and seat rings: Cast iron. Renewable.

Disc carrier pins: Steel. Renewable

Flanges

Flanged valves conform to American Standard Face to Face Dimensions, Ferrous Flanged Valves are to ASME dimension for 125 lb Cast Iron Swing Check Valves. Dimensions, drilling and facing of flanges conform to American Cast Iron Flange Standard, Class 125 (ASME B16.1-1975). Valves are interchangeable, size for size, with all other standard makes of swing check valves.

Fig 1572 N-4

Designed for use in oil, pulp and paper, wood treating process industries where line material is corrosive to trim on iron or IBBM valves. Bodies are nickel iron, and trim is stainless steel. Can be used either vertically or horizontally.

Bodies and Caps

Corrosion-resistant 3% nickel iron alloy. Discs 4″ is corrosion-resistant 18-8 MO. All other 3% nickel iron with stainless steel face rings. Renewable.

Disc carriers

Corrosion-resistant 18-8 MO (Type 316) stainless steel. Renewable.

Seat rings

Corrosion-resistant 18-8 MO (Type 316) stainless steel. Renewable.